An In-Depth Look at the Relationships Between Circular Economy, Environment, Social, and Governance (ESG), and Recycling Technologies

Transitioning to a circular economy will be critical to achieving a more sustainable future for a Recycling-Oriented Society. Actions such as technological evaluation from environmental, technical, and feasibility assessment of investment and planning for waste prevention, reduction, reuse, and recycling materials may dramatically cut yearly greenhouse gas (GHG) emissions. Suppose circular economy ideas are applied to the steel, aluminum, cement, chemical, and food industries; significant GHG reduction can be achieved.

As the worldwide emphasis on ESG grows, a circular economy might be a helpful framework for firms to make their goods and operations more sustainable. A circular economy focuses on the sustainable use of resources throughout the production process, where materials are utilized for many and recycled at the end of the product’s lifespan. It enables businesses to get more value from their resources while lowering the risk associated with their acquisition. Supply chain bottlenecks and fluctuating material prices are examples of such hazards. A circular economy also incorporates waste avoidance in production processes, which helps guarantee that items are more durable and may be reused several times.

Population growth and a growing middle class with higher consumption levels are putting strain on our resources worldwide. Producers must accomplish more with less to match limited resources with this demand. The impending climate disaster and other environmental concerns need corporations to utilize resources more efficiently and sustainably.

The European Commission’s new Circular Economy Action Plan, published in March 2020, applies the well-known core principles of resource utilization (reduce, reuse, recycle) to these present difficulties. The plan’s highlights include technology, trash, food and packaging, textiles, and plastics. Companies must identify and eliminate needless resource consumption and effectively use and manage current reuse and recycling streams.

For instance, the Japanese culture promotes the “3Rs” (reduce, reuse, and recycle), which are now recognized and implemented all over the world, and a society that places a high value on recycling (Recycling-Oriented Society). It is possible, for instance, to evaluate the similarities and differences between models of circular economies in Europe and Asia. The growth of the circular economy in Europe is astonishing. Every nation contributes knowledge or competence, and they all benefit from learning from the experiences of other nations. To fulfill all the responsibilities described above, it is typically necessary to include a company not directly involved, such as DEISO LLC. In addition, the nations have set critical and stringent goals for their Net-Emissions. With conservation, you also need to consider these factors.

What Is the Relationship Between a Circular Economy and ESG?

More businesses in various industries are using circular economy ideas to cut costs, enhance profits, and minimize risk. Besides the growing number of enterprises implementing circular economy efforts, the number of circular economy-related rules has grown. When integrated with more comprehensive ESG strategies, circular economy concepts can act as a framework for improving sustainability and disclosing sustainability performance to stakeholders.

ESG frameworks aid in determining which metrics (e.g., product producers) should focus on. When we think about the circular economy, we generally think of product actors. So, when a product maker is looking for metrics for disclosure, they want to look at their core business operations and the areas where they can create the most significant progress,”. A circular economy strategy may help product producers save costs by using resources better. Suppose product makers can drive improvements and mitigation measures across each product lifecycle stage. In that case, they are highly ripe and excellent for ESG disclosure.

A circular economy is a practical framework for minimizing GHG emissions from materials. With the Intergovernmental Panel on Climate Change (IPCC) proclaiming that the world must achieve net-zero emissions by 2050 to avoid the worst consequences of climate change, goods makers may help achieve that objective by lowering their GHG emissions. Besides the stated recycling rules set by the EU and other nations, attaining net-zero objectives is becoming required. To comply with these laws, product producers must handle emissions from the manufacturing process and the materials utilized.

Product producers may enhance their goods’ sustainability by undertaking a life cycle evaluation (LCA). LCAs may assist product makers in determining the quantity of waste generated during the production process, the number of raw materials utilized and the associated GHG emissions, and how waste is managed and recycled.

Once product producers have this information, they may identify GHG emissions hotspots and devise a strategy to address them. LCAs may be valuable for a more comprehensive circular economy strategy since they provide the data required to enhance product sustainability. The power of LCA will be discussed later in this article. Keep reading.

Recycling Technologies

Thermal, chemical, and material recycling technologies are becoming more effective in separating useable components from old materials, whether plastics, metals, or other complex substances. Thermal recycling methods employ heat to degrade materials into components that may be reused to produce new goods. Chemical recycling technologies utilize different solvents and catalysts to accomplish a similar purpose. Material recycling technologies use diverse physical ways to separate useable materials from waste. Thanks to these technologies’ continuing development and improvement, we can now recycle an ever-expanding spectrum of materials, including those that were thought too difficult or costly to recycle. This reduces the environmental impacts of material manufacturing and consumption and frees up resources that may develop new goods.

Pyrolysis is a promising method of thermal recycling. Pyrolysis is heating materials to high temperatures absent oxygen, causing them to decompose into their constituent elements. These components may then be disassembled and reassembled to form new products. Pyrolysis is already used to recycle various materials such as plastics, tires, and wood.

Chemical recycling methods are also improving in efficiency and versatility. One well-known example is hydrolysis, which involves using heat and water to break down things into constituent elements. These components may then be recombined to form new products. Various products, including plastics, tires, and metal oxides, are already recycled via hydrolysis. Material recycling methods provide a diverse and effective method of recycling various materials. Magnetic separation, which employs magnets to separate useable materials from garbage, is one prominent example. Metals, plastics, and paper are already recycled using this method.

What is Material Recycling

Converting trash into new goods and resources is known as recycling. This concept often considers energy recovery from waste materials. The ability of a material to reclaim the properties it had in its original state determines how recyclable it is. It is an alternative to the “conventional” form of waste disposal that may help preserve resources and minimize greenhouse gas emissions. It may reduce the need for new raw materials and prevent the waste of potentially valuable materials, reducing energy consumption, air pollution (from incineration), and water contamination (from landfilling).

Waste recycling technologies can decrease the garbage we generate drastically. Still, they also have their own set of disadvantages and limits. The most mature and effective method is thermal recycling; however, it can only recycle materials that can resist high temperatures. Chemical recycling is less efficient, but it can recycle more materials. Material recycling has the potential to recycle a wide variety of materials. Finally, the most effective recycling process will be determined by the material to be recycled.

Recycling is the third phase in the “Reduce, Reuse, and Recycle” waste hierarchy. It is an essential aspect of modern waste reduction. It promotes environmental sustainability by reducing raw material input and rerouting waste output in the economic system. ISO standards for recycling include ISO 14001:2015 for environmental management control of recycling practices and ISO 15270:2008 for plastics waste.

Glass, paper, cardboard, metal, plastic, tires, textiles, batteries, and electronics are all recyclable materials. Composting and other uses of biodegradable waste, such as food and garden waste, are also included in recycling. Recycling items are taken to a home recycling center or collected from curbside bins and sorted, cleaned, and reprocessed into fresh materials for manufacturing new products. d recycled into fresh materials for the production of new items

What Is the Mechanical Recycling?

Mechanical recycling is the more commonly known methodology, as this has been in operation for some time. This technology implies the recycling practice. We all refer to plastic waste recycling as other plastic products.

Chemical recycling is a relatively new collection of technologies recently gained popularity in the plastics recycling industry. The phrase “chemical recycling” refers to more than one technology—it refers to several methods of completing the loop. Chemical recycling is a disposal strategy that lies between incineration, which tries to maximize the use of stored energy in the material, and mechanical recycling, which keeps the macrostructure of a plastic intact, primarily by shredding and remelting a sorted percentage of a particular polymer.

Chemical recycling covers a variety of processes, such as pyrolysis, hydrolysis, and gasification. Chemical recycling techniques seek to close the loop by dissolving plastics into monomers or providing gases and condensates that may be fed into the chemical processing streams of large chemical plants worldwide. Manufacturers may generate high-performance plastics with virgin-equivalent quality through chemical recycling (e.g., for food).

Advanced or chemical recycling, again, is a relatively new technology. It is complementary to mechanical recycling because it can recycle a more comprehensive range of plastics rarely accepted by mechanical technology. There are several ongoing projects in the plastics and recycling industries to make advanced recycling more widespread. Chemical recycling is a cutting-edge plastic waste technology that offers several manufacturer opportunities.

What is the technique? Plastic waste is broken down into its component molecular components by chemical recycling. When plastic is broken down in this way, the chemistry of its polymers is hurt, allowing for their reconstitution back to their original essential components, where they may then make new polymers or petrochemical feedstock.

What Thermal Recycling

Compared to energy-from-waste (or WtE/Waste-to-Energy) technology, advanced thermal recycling (ATR) is a critical advancement. Using an ATR system, municipal solid waste (MSW) can be converted into electricity or steam used for industrial users or district heating. Fly ash from combustion processes, combustion bottom ash from combustion processes, and air pollution control system fly ash from air pollution control systems is all treated to create materials that may be reused. These systems are helpful for ATR: Systems for processing combustion bottom ash and fly ash to produce commercially viable products; and equipment for reclaiming energy and reducing air pollution. Before MSW enters the facility, it can be preprocessed to recover recyclable materials. Methane is a Greenglass and a significant contributor to climate change can be captured from landfills or utilized from biogasification processes to produce electricity. Incineration plans can also be used for WtE to produce electricity.

Bringing the Circular Economy and ESG Full Circle

Product producers can apply the framework of a circular economy to lower product emissions, limit risk throughout the process of material acquisition, comply with laws, and fulfill the needs of stakeholders. Suppose companies include the concepts of a circular economy into a more comprehensive strategy that addresses environmental, social, and governance issues. In that case, it may be simpler for them to figure out how to enhance the long-term sustainability performance of their operations. It is possible that carrying out life cycle assessments, also known as LCAs, might be of utmost significance in collecting data necessary to cut down on emissions of greenhouse gases and guarantee higher sustainability.

What is Life Cycle Assessment (LCA)?

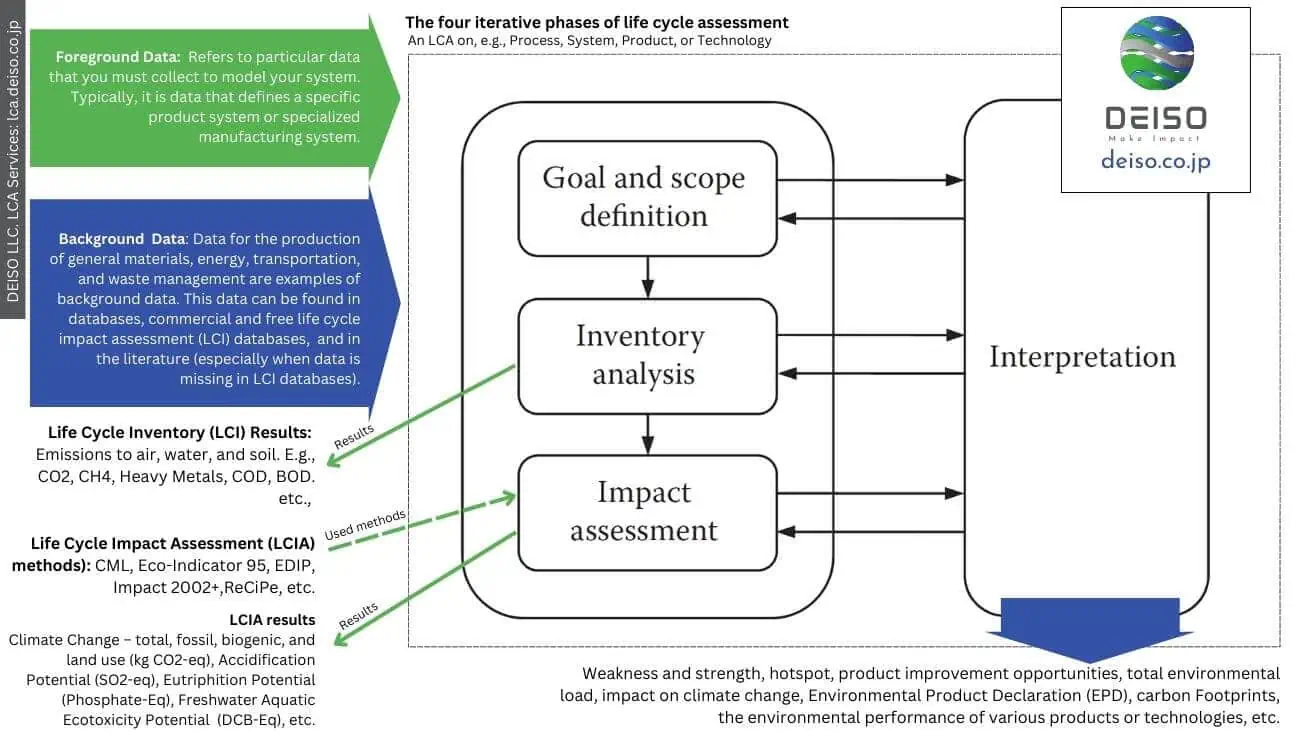

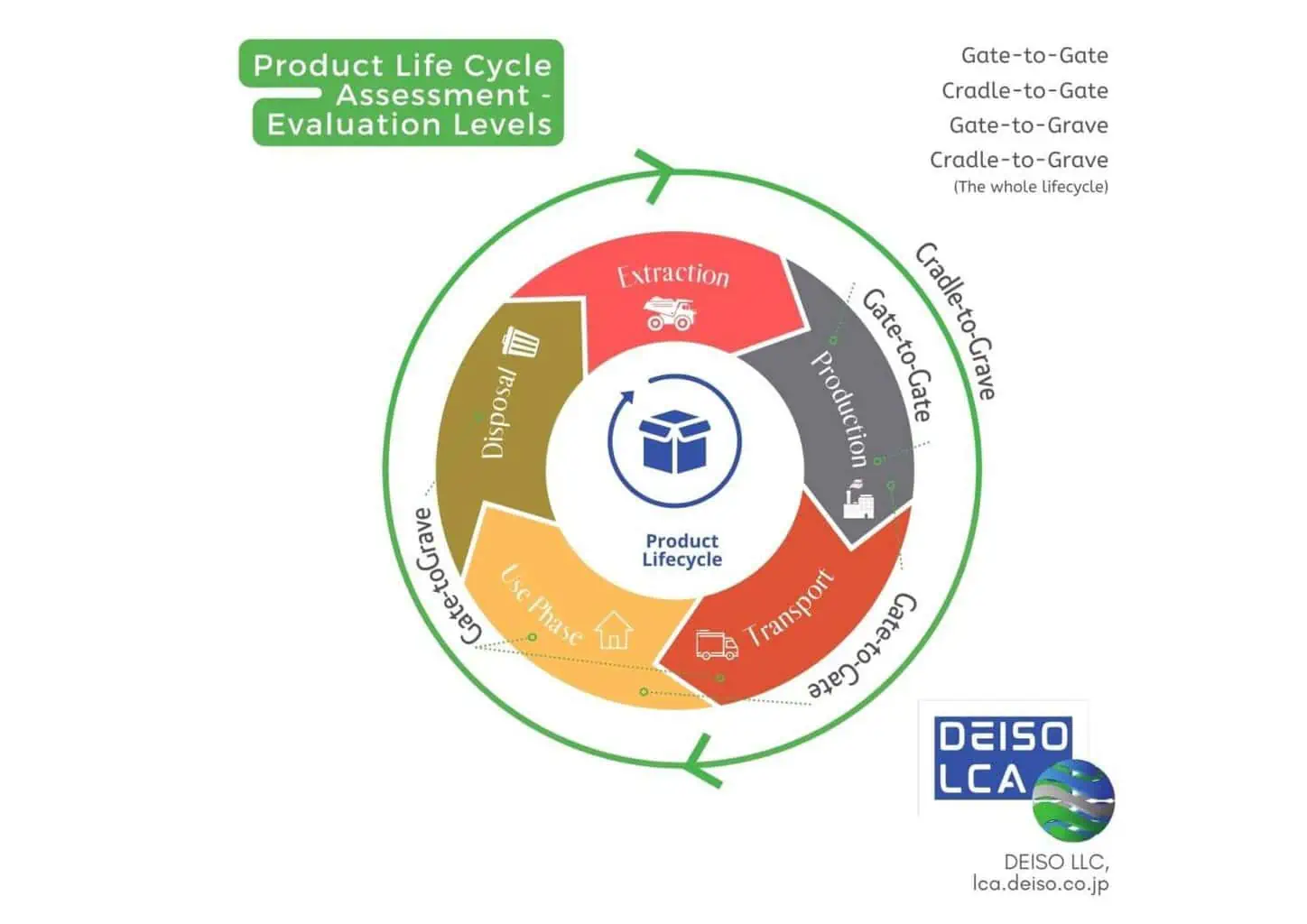

Cradle-to-grave analysis sometimes called a life cycle assessment (LCA), examines how a product affects the environment during its entire existence. Cradle-to-grave evaluation LCA is often used to compare how different products and services affect the environment. The cradle-to-grave technique for evaluating environmental impact considers a product’s impacts across its entire life cycle, from creation to disposal. To identify which activities or products have the most negligible negative impact on the environment and which designs are the most environmentally friendly, apply the LCA technique.

The life cycle assessment (LCA) approach may be used for any process or product production, from tomato farming to car assembly. Environmental repercussions occur off-site (e.g., emissions to air and water, solid waste). The goal of LCA is to identify and measure the environmental effects associated with every stage of a product’s life cycle, including:

- Extraction of resources and raw materials

- Production/manufacturing

- Transportation and distribution

- Waste: End of Life

The LCA approach helps determine a product’s environmental effects and environmentally friendly design. An analyst with specific expertise does LCA and is to gather data on every stage of a product’s life cycle before putting that data into a computer program. The analyst will next evaluate each stage of the product’s life cycle’s impacts on the environment and assign a weight to each impact. The weight assigned to the stage is determined by considering its environmental impact and relative contribution to the product’s total environmental impact. An LCA’s ultimate output describes a product’s environmental profile and makes recommendations for reducing its harmful impacts on the environment.

The Power of Life Cycle Assessment (LCA): The Link with Circular Economy & Recycling Technologies

But how can we know which chemical recycling processes to use on different plastics? And why should we use them when mechanical recycling is already a tried-and-true solution? In what situations can chemical recycling lessen the overall environmental effect while completing the material loop and minimizing the requirement for virgin resources?

These are critical issues, particularly at this stage in developing, demonstrating, and piloting innovative chemical recycling processes. Life Cycle Assessment is a tried-and-true, internationally-defined method for analyzing and assessing the environmental effect of goods and activities (LCAs).

Previously, LCA was mainly used for linear systems. A linear system (from the cradle to the grave) considers take-make-waste. Companies may undertake an LCA in such a system by analyzing and aggregating the effects at each life cycle step. Comparing items from various manufacturers or manufactured using different procedures is relatively simple.

Applying LCA to circular systems, particularly chemical recycling technologies, presents problems and methodological issues. Comparing systems in circular systems is more complicated, particularly when connecting operations from one life cycle to the next (as in chemical recycling). Chemical recycling encompasses various processes, various kinds and grades of intermediates, recycling quality, and product uses. Without agreement on methodological decisions, such as system extension or differential methods, a direct comparison of such systems is not as easy as one would anticipate.

It is still unclear how to define the system boundaries for chemical recycling systems and new goods generated from chemically recycled chemicals. Establishing which LCA technique businesses should use for chemical recycling is also critical. Should a corporation prioritize trash removal above alternative disposal techniques such as incineration or mechanical recycling? Should a company compare chemically recycled feedstocks/products to their traditional virgin equivalents from a product-use standpoint?

So far, we have increased transparency about the problem of developing a uniform strategy for LCA implementation for chemical recycling systems. To address this difficulty, individual companies, the rising industry, and the market for chemical recycling must work together.

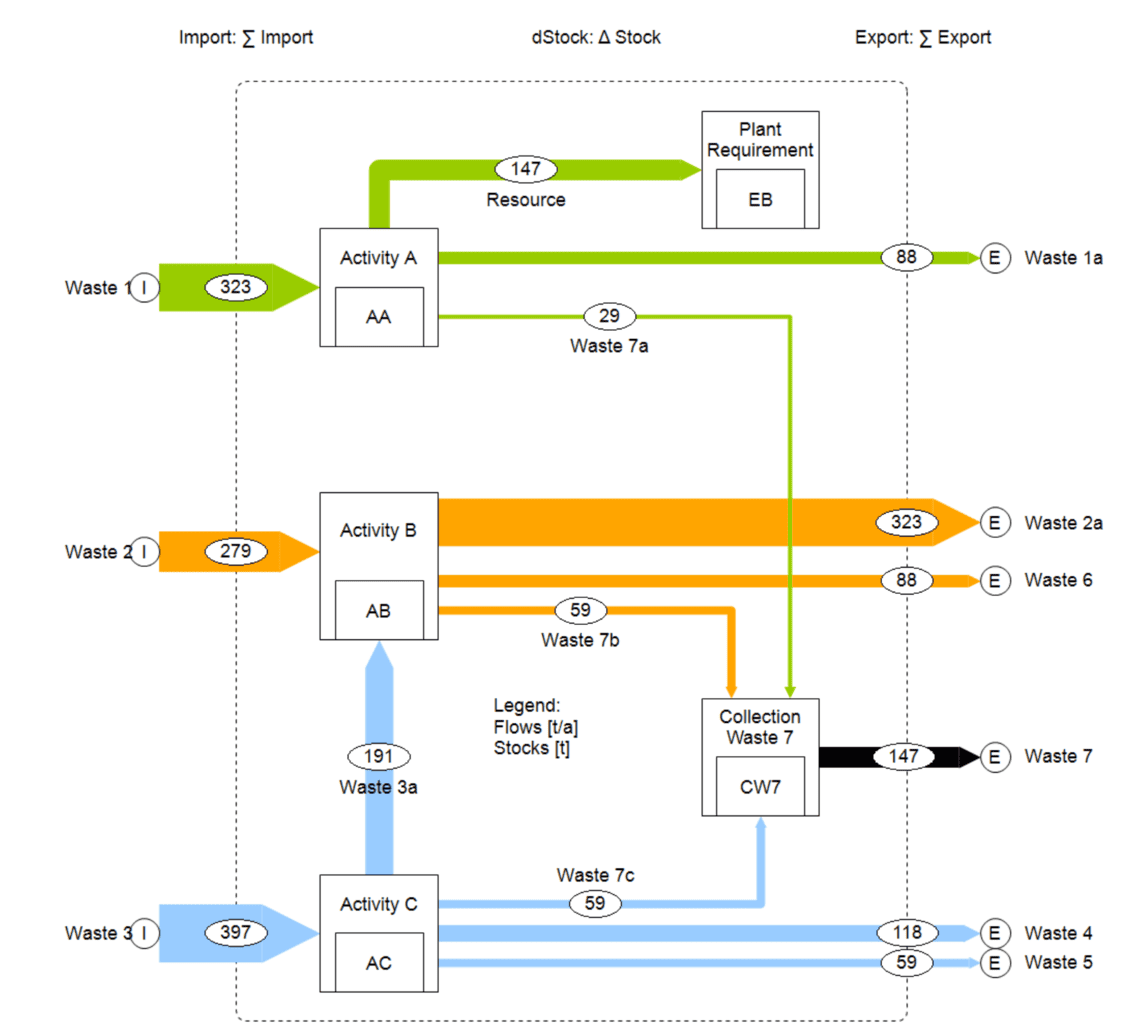

The Importance of Material Flow Analysis (MFA) and how it can incorporate within the closed loop

MFA makes it possible to conduct an organized accounting of the transportation and storage of various materials throughout an area for a certain amount of time. The word “materials” may apply to various manufactured goods and specific chemical components. This is because the phrase covers both categories. Materials like uranium, copper, steel, and aluminum are a few examples of things often covered in-depth throughout an MFA degree. The mass balancing notion, taken from the law of mass conservation, is the fundamental tenet around which the MFA is built. Therefore, it is necessary to balance the inputs and outputs of materials and any losses or stockpiles that may occur (i.e., accumulation). MFA may encompass all aspects of a material’s life cycle, such as its mining, use in manufacturing, and the management of its waste. It is helpful for research on resource scarcity to employ MFA since it considers material stocks and material flow besides material fluxes. Monitoring material flows over an extended period often makes it feasible to research longer-term tendencies in material use. The MFA is a valuable tool for determining the resource productivity of an economy. However, it is not suitable to consider singular production systems.

How DEISO Can Help in Your Projects

Often, it is necessary to enlist the assistance of a third-party firm such as DEISO LLC for the concerns and the described technicalities, sustainability assessment, and evaluation methods above. In addition, global Net-Emissions targets are in demand in the countries that have begun this process. They should also be considered during conservation efforts. Therefore, large organizations may collaborate with DEISO to execute such projects or research in the industrial world. DEISO Speaks fluent LCA, MFA, circular economy, and waste management and speaks the language of recycling, resource efficiency, and chemical processes simulation.

Further Readings

Further Readings

- Learn about our Multicriteria Technology, Startup, and Project Evaluation

- Learn About our circular economy Services

- Learn about Life Cycle Assessment (LCA) services

- Learn about our Material Flow Analysis (MFA) services

- Learn about our Waste and resource management services

- Learn about our chemical process modeling and simulation services

- Learn about our human resource development service of professional training programs

Get Started: Contact Us

Need help with your next project? Let’s talk. Feel free to introduce your project concept to us, and we will be happy to schedule a remote meeting with you. Please get in touch with us via this online form.

Need a quote? Please submit the Request a Quote from here.

Share this:

- Click to email a link to a friend (Opens in new window) Email

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to share on X (Opens in new window) X

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Reddit (Opens in new window) Reddit

- Click to print (Opens in new window) Print

- More

- Click to share on Tumblr (Opens in new window) Tumblr

- Click to share on Threads (Opens in new window) Threads

- Click to share on Pinterest (Opens in new window) Pinterest

- Click to share on Pocket (Opens in new window) Pocket

- Click to share on Telegram (Opens in new window) Telegram

- Click to share on X (Opens in new window) X