What is Material Flow Analysis (MFA)?

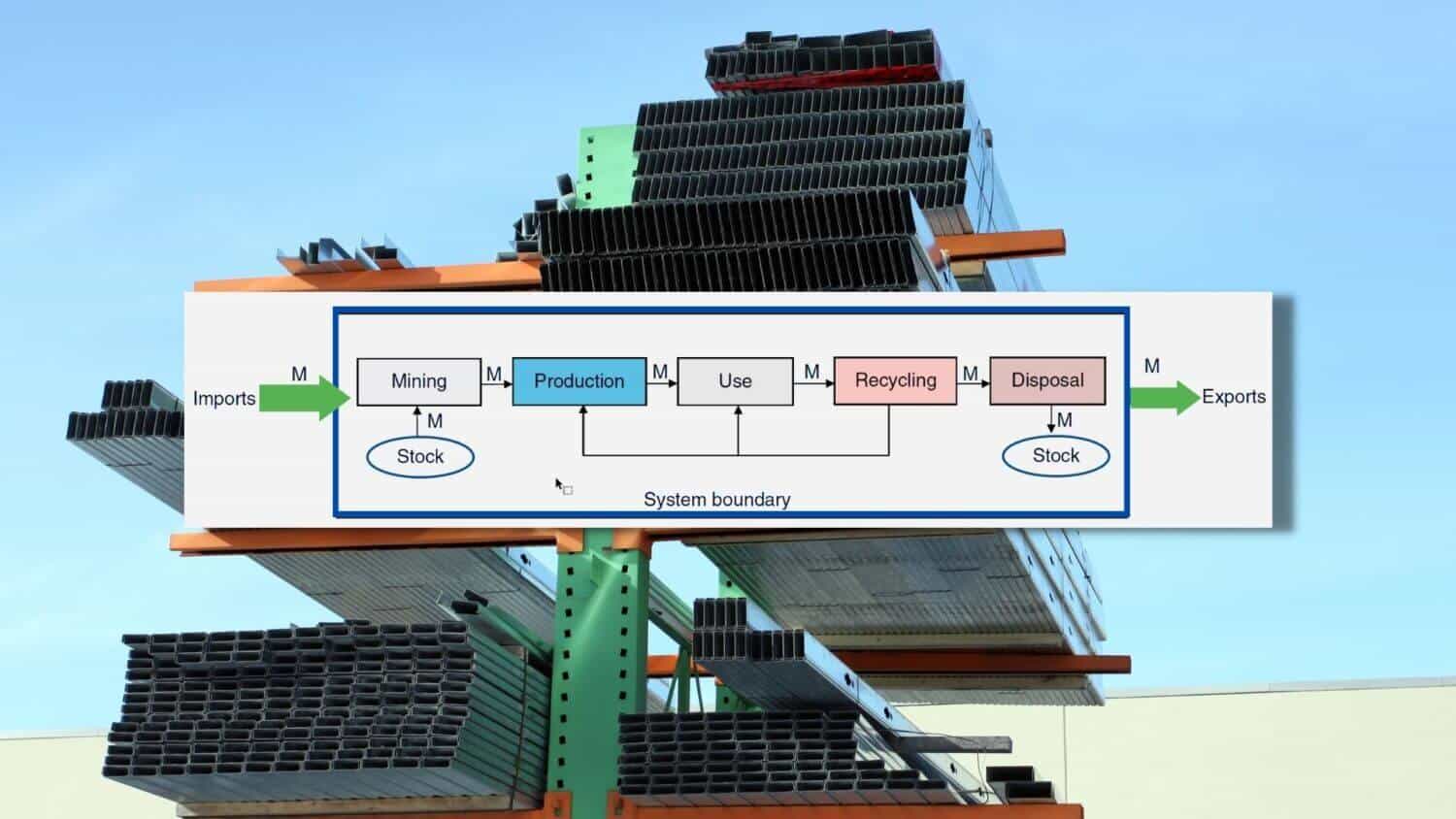

Systematic accounting of the movements and stockpiles of various materials during a specific period in an area is made possible by MFA. The definition of “materials” is comprehensive, including individual chemical constituents, compounds, and manufactured things. Aluminum, steel, copper, and uranium are a few materials often researched as part of an MFA program. The mass balancing concept, developed from the law of mass conservation, is the foundation of MFA. This implies that materials inputs and outputs, with any losses or stockpiles, must be balanced (i.e., accumulation). MFA may cover a material’s life cycle, including mining, manufacturing usage, and waste management. MFA is appropriate for resource scarcity research because it considers both material stocks and material flow besides material flows. Typically, material flows are monitored for years, allowing for the study of long-term patterns in material utilization. MFA may also calculate an economy’s resource productivity. However, it is not appropriate to consider single production systems.

The Material Flow Analysis (MFA)

Therefore, MFA assesses the flow of materials and goods in a production or distribution system. MFA can help identify areas where improvements can be made to optimize the flow of materials and goods, improve efficiency, and reduce costs.

The objective of MFA is to examine the flows and stocks of any material-based system; MFA is a suitable instrument. It provides information on the system’s behavior. Integrating with other fields like energy flow, economic, and consumer-oriented analysis makes it easier to manage an anthropogenic system. The goals of MFA are to:

Evaluating the movement of materials and goods in a manufacturing or distribution system is known as the primary goal of an MFA study. It can find places where the flow of materials and interests can be optimized, ultimately leading to greater efficiency and lower costs.

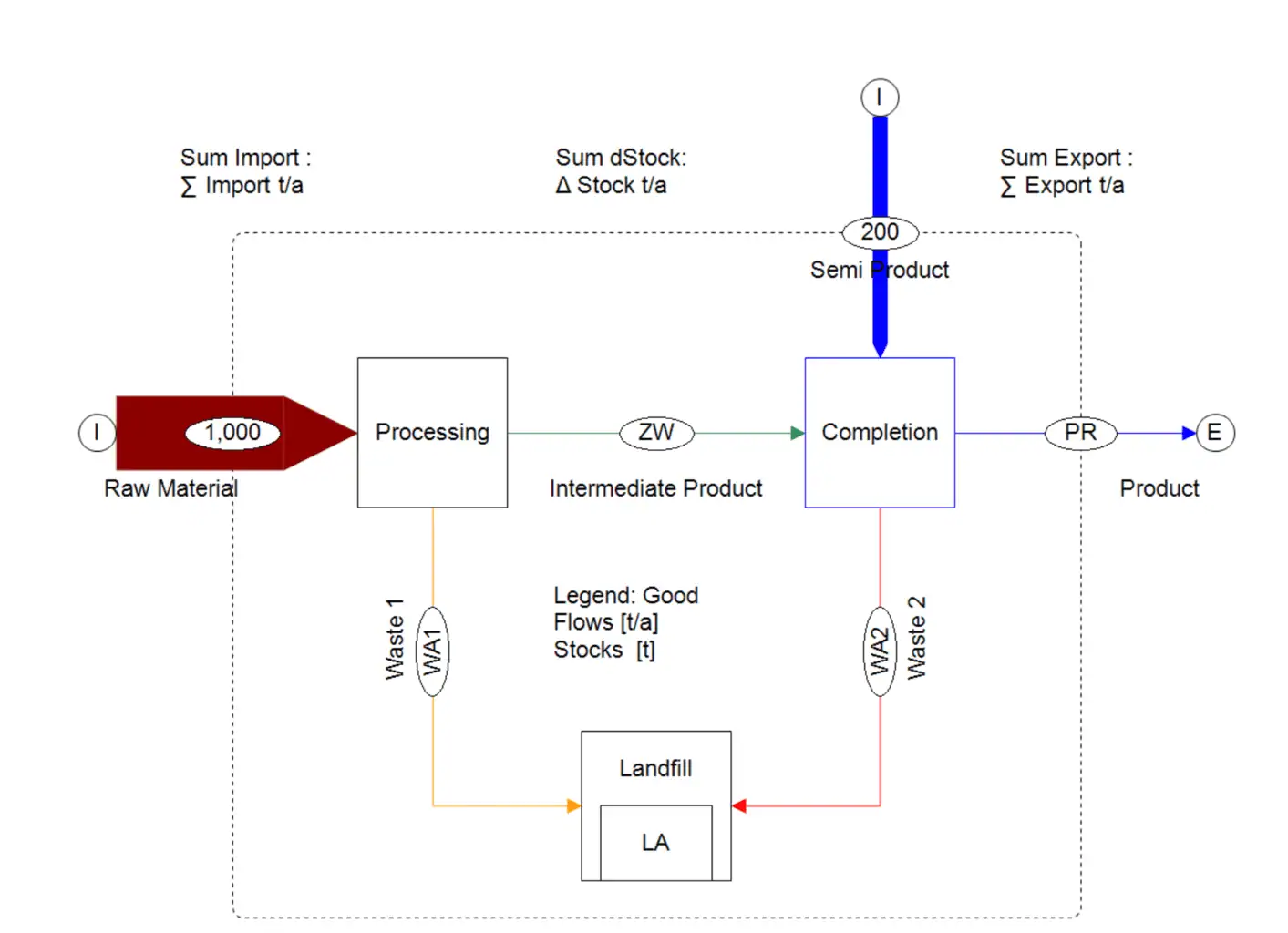

An Example of a Material Flow Analysis (MFA) Model

MFA is frequently used with other analytical methods like process mapping and value analysis to understand a production or distribution system more deeply. The use of an MFA depends on the organization’s requirements; MFA can be applied in several ways. The following are some typical MFA applications:

- Locating inefficiencies and waste in a production or distribution chain.

- Enhancing a production or warehouse facility’s operations.

- Enhancing the movement of supplies and products through a supply chain.

- Evaluating the effects of production and material handling on the environment.

The importance of MFA

Because it may assist businesses in increasing the effectiveness of their production and distribution networks, MFA is significant. This may cause financial savings and lessen the environmental effect of material handling and production.

MFA is a business tool to boost an organization’s performance by improving the flow of materials. It is also employed to locate and address production-related bottlenecks. The objective of MFA is to increase manufacturing process effectiveness, which enables the bottom line of the business. As a data-driven strategy that depends on precise data regarding the flow of materials. At various stages of the production process, inventories of the materials are taken to gather this data. MFA uses is used to develop a model of the manufacturing process. To locate and address production process bottlenecks, utilize this approach.

Understanding the Material Flow Analysis System and Its Key Definitions

An Example of a Material Flow Analysis (MFA) Model

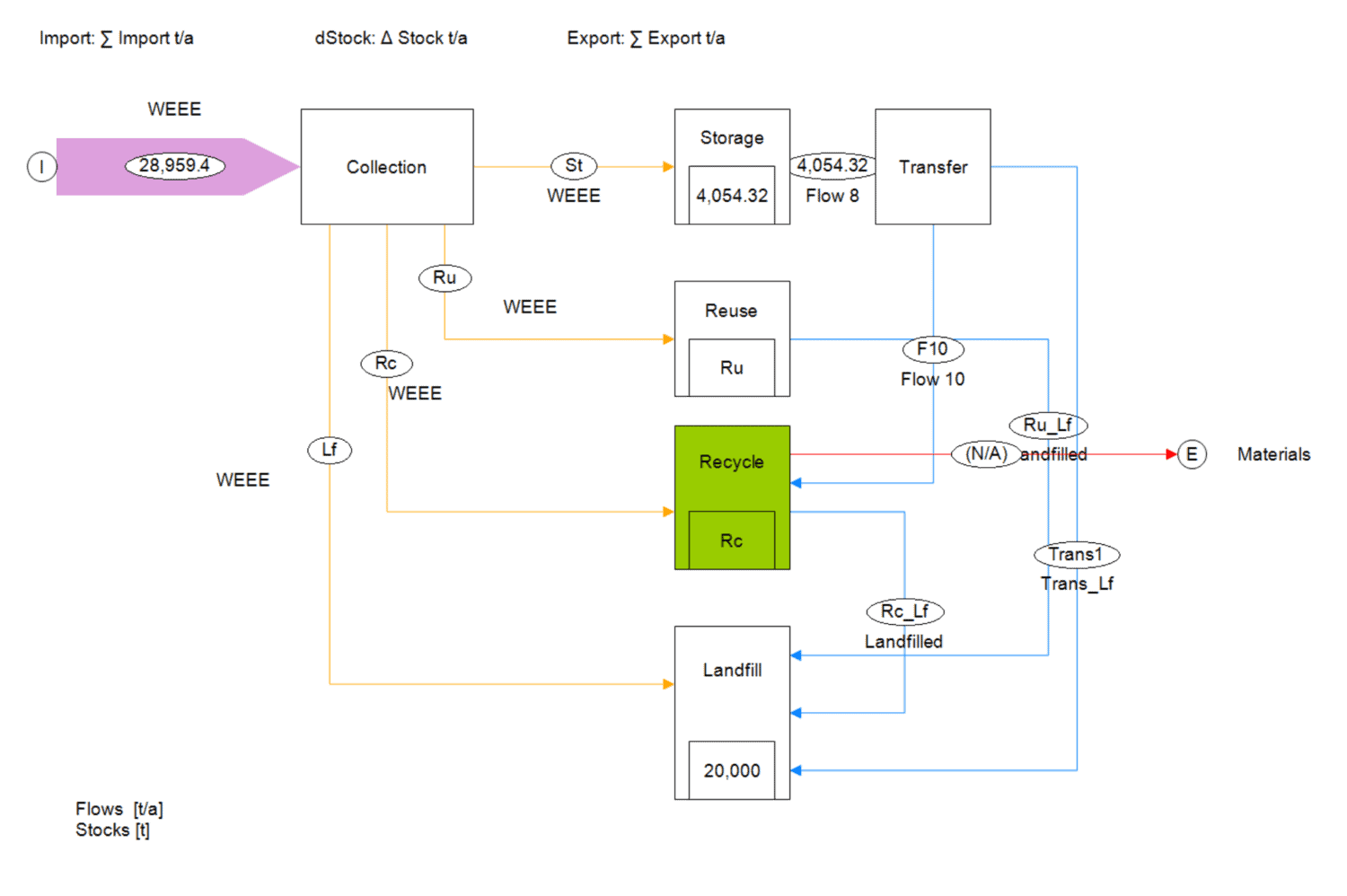

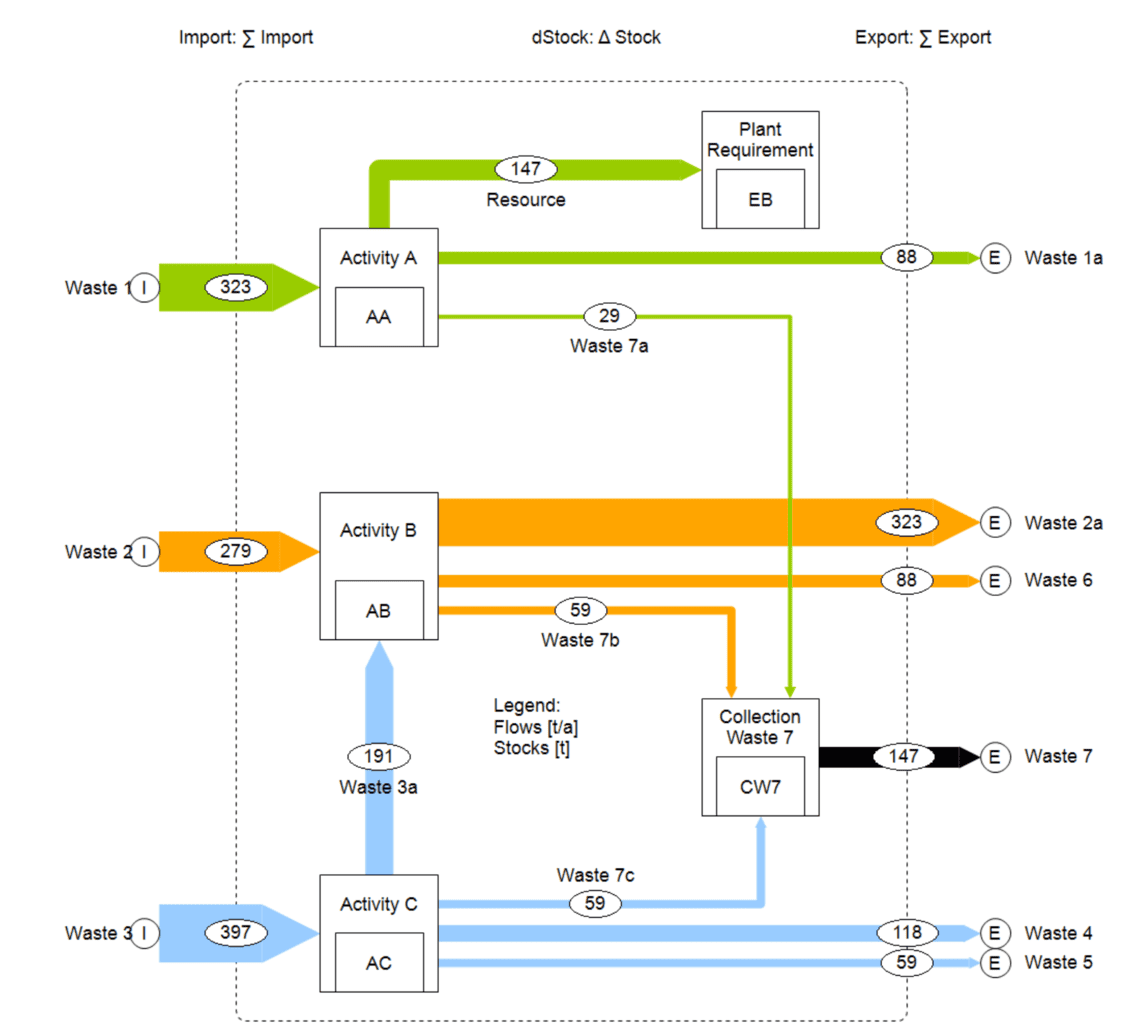

The systematic evaluation of the flows and stocks of materials within a system characterized in space and time is known as MFA. It links a material’s sources, routes, and intermediate and ultimate sinks. A straightforward material balance may manage the outcomes of an MFA that contrasts all inputs, stocks, and outputs of a process because of the rule of the conservation of matter.

The approach is appealing as a decision-support tool in resource management, waste management, and environmental management because of this distinctive feature of MFA. An MFA provides information on all flows and stocks of a particular material inside a comprehensive and consistent system. The flow of wastes and environmental loadings may be seen, and their origins can be found by balancing inputs and outputs. Early detection of material stock depletion or accumulation allows for implementing preventive actions or encouraging more expansion and future use. And minute adjustments that cannot be seen in the short term but might gradually cause long-term harm also emerge. There is more to anthropogenic systems than material movements and stocks. If the anthroposphere is to be handled responsibly, it must consider energy, space, information, and socioeconomic challenges. MFA may be carried out without taking these elements into account.

Still, these additional considerations are necessary for most circumstances to comprehend and use the MFA findings. MFA is commonly combined with economics, urban planning, and other relevant topics analyses. For the examination of anthropogenic systems, a common language is required. This similarity makes it easier to compare the outcomes of several MFAs in a visible and repeatable manner. This manual defines vocabulary and processes for analyzing, describing, and modeling material flow systems, allowing for a thorough, repeatable, and transparent accounting of all material flows and stocks inside a system.

The word “material” refers to both things and substances. According to the chemistry definition, a substance is a single matter made up of uniform units. The material is an element if the building blocks are atoms, like carbon or iron, or a chemical compound if the building blocks are molecules, like carbon dioxide or iron chloride. Substances or combinations of substances are considered goods when marketplaces give them economic worth. The value may be positive (for example, a vehicle, gasoline, or wood) or negative (municipal solid waste, sewage sludge). The term “goods” is generally used in economics to refer to immaterial items like energy (such as electricity), services, and information. However, in MFA terminology, the word “goods” exclusively refers to tangible objects. But when MFA is utilized, for instance, to make judgments about resource conservation, the relationship between goods defined by MFA and other goods used by economists might be significant. Transport, change, or storage of materials are all processed.

The movement of dissolved phosphorus in a river is an example of a natural transport process. It may also be an artificial activity, such as gas flow in a pipeline or waste collection. The same is true for storages and transformations (such as the oxidation of carbon dioxide by natural forest fires vs. artificial heating systems) (e.g., natural sedimentation vs. artificial landfilling). Stocks have the physical unit of kilos and are defined as material reservoirs (mass) inside the examined system. A stock is a process component consisting of the mass kept within the process. Stocks play a crucial role in a system’s metabolism. The mean residence time of material in stock may be computed under steady-state circumstances (input equals output) by dividing the material mass in the stock by the material flow into or out of stock. Stocks may rise or decrease in size due to material accumulation or depletion. Materials’ flows (mass per time) or fluxes (mass per time and cross section) connect processes. Imports and exports are flows or fluxes that occur across system boundaries. Those entering a process are known as inputs, while materials leaving are known as outputs.

A system comprises several material flows, stocks, and processes within a predetermined boundary. The smallest system comprises simply one process. The following are examples of typical systems that MFA examines: a region, a municipal incinerator, a residential home, an industry, a farm, etc. Space and time are used to define the system boundaries. When the system boundary in time is chosen, factors such as objectives, data availability, appropriate balancing period, the residence time of materials within stocks, and others must be considered. It can comprise physical borders (region) or virtual limits (e.g., private households, including processes serving the private household such as transportation, waste collection, and sewer system).

An Example of a Material Flow Analysis (MFA) Model

Substance: Any (chemical) element or compound composed of univariate units is a substance. All substances (such as N, C, Cu, NH4+, and CO2) are homogeneous because they each have a distinct and identical constitution.

GOOD: Economic entities of matter having a positive or negative value are goods (e.g., drinking water, fuel oil, solid waste, sewage, respectively).

Some products, such as air, exhaust, or precipitation, are neutral in terms of value, meaning they have no economic worth.

MATERIAL: The word “material” is used to refer to both substances and objects. Thus, it encompasses all naturally occurring materials and those that have been altered physically or chemically.

PROCESSES: When examining products and substances, or when it is not yet evident whether an examination will be conducted at the level of goods or substances, the word “material” is employed. Transformation, transportation, and storage of goods and substances are processes.

STOCK: The “stock of materials” refers to the entire quantity of materials kept in a process.

Here are stock examples:

- The waste in an incineration facility – fresh garbage causes the stock to rise, while incineration causes the stock to drop

- The building is a component of the infrastructure – the stock increases when a new building is constructed. The stock decreases when a building is demolished.

FLOW is the ratio of mass per unit of time that passes through a conductor, such as a water pipe. It is possible to specify the physical division of flow in terms of kg/sec or t/yr.

FLUX: is a flow per “cross-section,” according to the definition. A person, 1 m2 of surface area, or an entity like a private home or business are often utilized cross sections in MFA. The flux may be expressed in units such as kg/(sec.m2).

SYSTEM: A system comprises several components that interact with one another. The members of a system are called processes and flow in MFA. An outline might be a company (such as a waste incineration facility), a region, a country, or a single-family home.

Every product in an MFA system may be precisely recognized via an original and a target procedure.

SYSTEM BOUNDARY: The system boundary is established in time and space (temporal and spatial system boundaries). For anthropogenic systems like a company, a city, or a country, periods of 1 year are often used as the time limit due to data availability. The geographic region where the processes are situated usually determines the boundaries of the spatial system.

Imports are flows into a system, while exports are movements out of a system.

What is Substance Flow Analysis (SFA)?

When a single substance is the focus, MFA, also known as SFA, is a methodical evaluation of the status and changes of flows and stocks of materials within a system specified in space and time. MFA links a material’s sources, routes, intermediate sinks, and final sinks. The outcomes of an MFA may be managed by a straightforward mass balancing that contrasts all inputs, stocks, and outputs of a process because of the law of conservation of matter. The approach is appealing as a decision-support tool in resource management, waste management, environmental management, and policy evaluation due to this distinctive feature of MFA.

However, SFA is a particular subtype of MFA that focuses on chemical elements or molecules. Most SFA studies’ primary objective is to offer knowledge for regional or national strategic management of chemical substances. SFA can monitor environmental contamination over time in a particular area. Pollution emissions from various sources to a specific area’s air, water, and land. However, the line separating MFA and SFA is frequently blurred, and the two phrases are occasionally interchangeable.

How Can DEISO Help Your Organization With MFA?

- Visit our MFA page here to learn about our MFA services from analysis and evaluation.

- DEISO also provides training programs for MFA and its software.

- See also our Circular Economy services and the Life Cycle Assessment services, which represent an integrated approach with MFA for better sustainability, resource efficiency, supply chain, and environmental performance.

- See also our services for Waste Management Systems.