Background

Where the concepts of sustainability are often debated, but putting it into practice is harder. Declarations and actions must be taken as quickly as feasible after an investigation to minimize environmental damage and improve upon previous efforts. Three requirements must be met, though: a possible action to be taken, the alternatives must be prioritized, and the best practices must be chosen while considering the cost, environmental impact, and economic constraints.

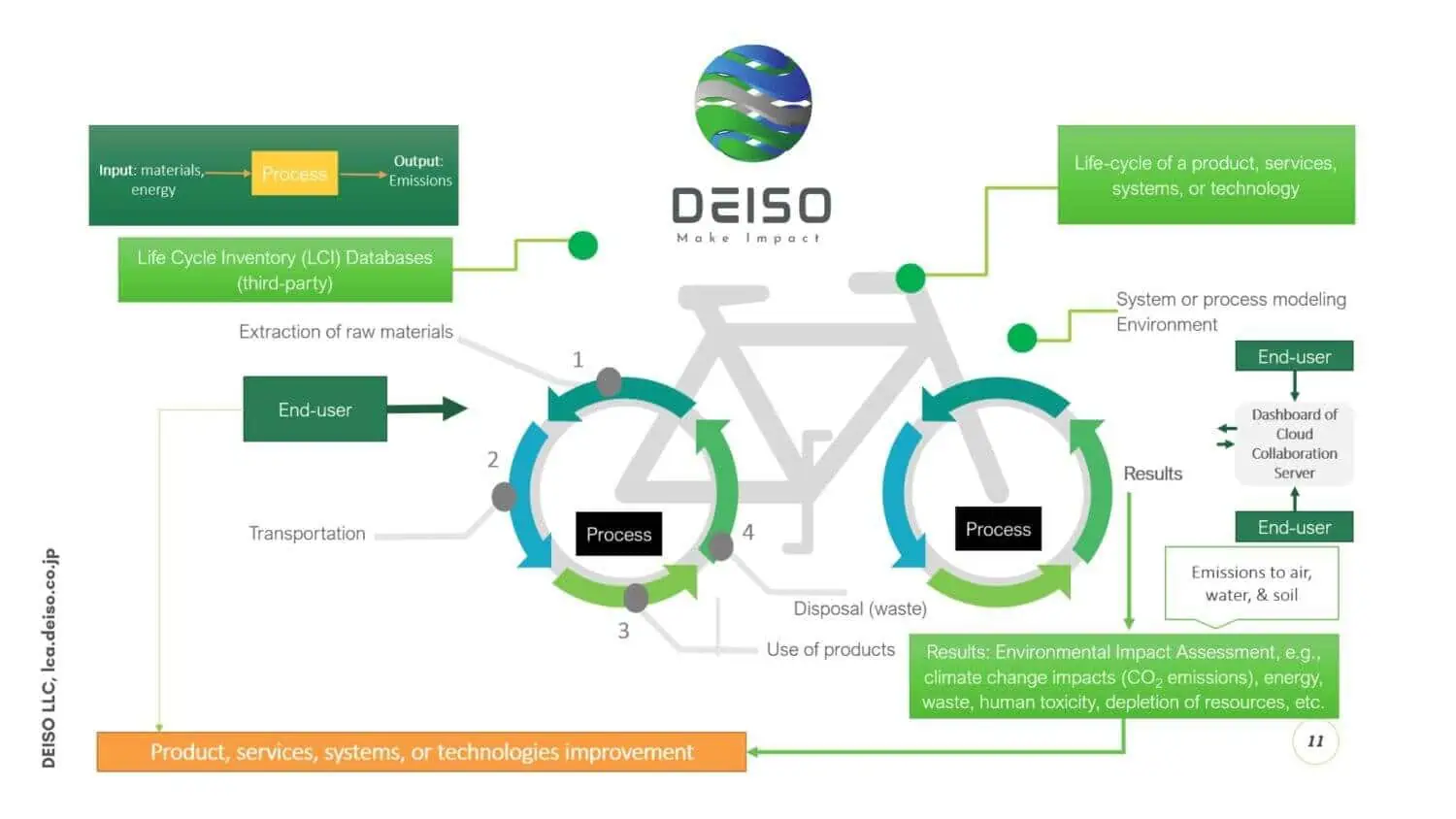

The Life Cycle Assessment (LCA) is a decision-making tool that helps choose and optimize the technology solutions or products available to meet this demand. The question is not how to solve a particular case of tight money. Engineering is already general or may take care of it. The problem is how to set priorities. Sadly, the world cannot afford to fund everything. LCA complements modern advancements because it shows the procedures that must be changed the most. From the standpoint of sustainability, LCA is very critical. This is because it encompasses a product or service’s lifecycle. This prevents local improvements from being the sole ones that cause the environmental effect to be moved elsewhere. The strategies for evaluating ecological performance, practical use of raw materials, and pollutant emissions depend on the system’s or item’s purpose, which was not the case with previous environmental assessments.

Practical activities that minimize environmental harm must be undertaken after investigations. Therefore, some prerequisites must be met for a move to be effective:

- Practical activities that minimize environmental harm must be taken after investigations.

- Environmental impacts evaluation, which may even make things better. For an action to be effective.

What Is Life Cycle Assessment (LCA)?

The Concept of LCA

The LCA is a methodology used to assess a product’s or system’s environmental impacts throughout its life cycle, from the cradle to the grave. LCA tries to identify and quantify the ecological effects of a system or product that can help decision-makers make more sustainable decisions. LCA is a powerful tool that determines how different products and procedures affect the environment. It is used to figure out how cars, buildings, and food systems affect the environment. It is a complete approach that considers every step of a design or product’s life cycle, from getting the raw materials to making it, using it, and disposing of it.

LCA is a complex process, and a detailed field is often used to compare the environmental impacts of products and services. It can be used at various levels, from local to global.

Several assessment methods and approaches can be used. The most important thing is to choose the best method and procedure for evaluating the product or system. The results of an LCA can tell decision-makers how different sustainable options are and help them choose the most sustainable one. LCA considers the following:

- Extraction of raw materials.

- Production of the product.

- Use of the product.

- Transportation and energy use.

- Waste management.

What Is Life Cycle Assessment (LCA)?

- LCA can help businesses identify and reduce environmental impacts.

- LCA can help identify sustainable business practices.

- Can help develop greener technologies, products, and systems.

- It can help understand the impacts of climate change on the environment and health and assess approaches to combat it.

- It can help compare several products, technologies, or future scenarios with a baseline one (e.g., the current situation).

- Help improve the environmental performance of technologies.

- Answer the big questions regarding environmental and sustainability concerns, especially when integrated with other sustainability assessment methods.

- It can help identify the weak points in products, technologies, and services.

- For consumer benefits: LCA can help consumers make informed decisions about the products they buy.

What is Life Cycle Assessment (LCA)?

LCA is an analytical way to figure out how a product affects the environment at every stage of its life, from the cradle to the grave. LCA can help make a product or process less harmful to the environment and find the most eco-friendly way to design it. It is an analytical and comprehensive technique for any product or process, from manufacturing a car to growing a tomato. LCA tries to find and measure the environmental effects of a product at every stage of its life, such as:

- Resource extraction and production.

- Use and End-of-Life.

- Transportation and distribution.

- Off-site environmental impacts (e.g., emissions to air and water, solid waste).

An LCA can help determine how a product affects the environment and which design is best for the environment. An LCA is performed by a specially trained analyst who collects data on all stages of a product’s life cycle and then inputs that data into a software program and models the system. It can be done by hand calculation though it is a time-consuming process. Often, using LCA software can significantly accelerate the process of conducting LCAs. The analyst then looks at how each step of the product’s life cycle affects the environment and gives each weight. The weight is based on how the stage affects the environment and how much that stage adds to the overall effect of the product on the environment. The output of an LCA includes a product’s environmental profile and recommendations for reducing environmental impacts.

Type of LCA Studies

Type of LCA Studies

- Screening LCA: The screening LCA can estimate how environmentally friendly a product, service, or manufacturing process is. A Lifecycle Inventory (LCI) database, which includes thousands of processes and sectors, can estimate the overall environmental performance of a product, service, or manufacturing process. This study calculates and evaluates several impacts, including eutrophication, acidification, human toxicity, and climate change. Using this approach, we can better understand the adverse effects associated with production processes. We can estimate the negative or positive impacts when selecting a particular product will positively or negatively affect the company’s environmental profile. This LCA helps determine a system’s overall environmental load, product, service, or technology.

- Product LCA: The product LCA examines the environmental performance of products and technologies from conception to disposal. Every aspect of its production cycle is covered from extraction to disposal instead of being disposed of improperly. This can lead to problems such as pollution caused by landfilling, incineration, or hazardous waste disposal.

- Comparative LCA: It considers the environmental impacts of all aspects and stages of a product or process, accounting accurately for its implications. A common LCA study type is when you compare two products or technologies, such as one technology, with another; however, this approach can also be used in other situations (e.g., comparing development routes).

LCA vs. Environmental Impact Assessment (EIA)

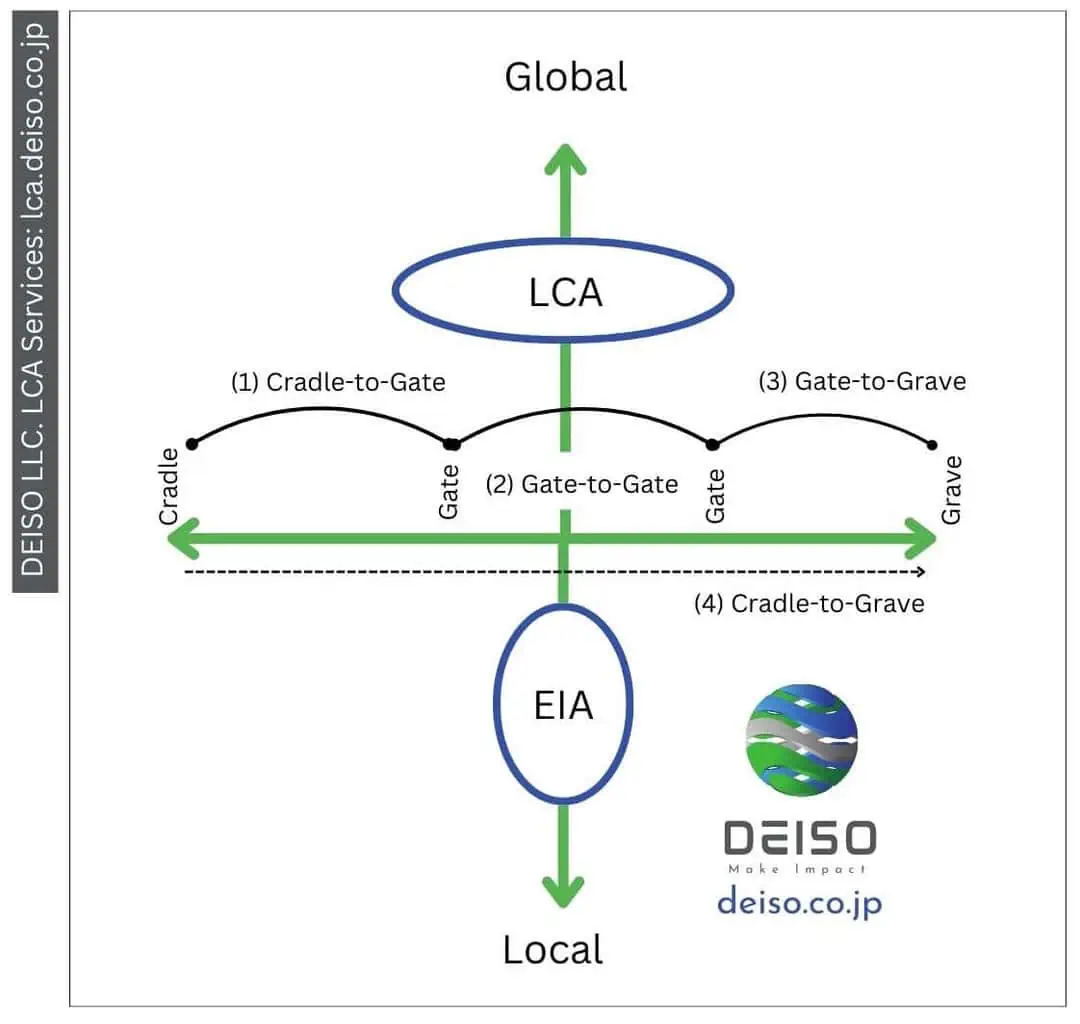

Comparing LCA and EIA across complementary time and geographical scales demonstrates the complementarity of the two instruments. An LCA evaluates a product or service from its extraction (cradle) to its End-of-Life (grave), if needed, on a global scale. At the same time, an EIA examines a single location. Site-specific EIAs consider variables specific to the location, such as the number of people living nearby, the distance between the site and residential districts, and the presence of particular ecosystems.

Life Cycle Assessment vs. Environmental Impact Assessment

Conclusion

LCA is a valuable tool that determines how products affect the environment and where they can be improved. LCA can help companies reduce the environmental impact of their products and make better decisions about how to design them and what materials to use.

Extraction of Raw Materials

Extracting natural resources means removing materials from the earth to manufacture or sell as commodities. Raw materials are the things extracted, such as coal, oil, gas, and metals. The extraction process can be hazardous and negatively affect the environment if not done responsibly. Oil and gas are extracted by drilling into the earth and pumping the fuel out of the ground. This can be done using traditional methods or fracking, which uses high-pressure water to break up the rock and release the energy. Mining involves removing the earth above the coal deposits. Drilling consists of extracting coal from the ground using a giant drill.

Metals are typically extracted through mining. In this process, the earth is dug away from the metal deposits, and special tools are used to pull out the metal. The metal is cleaned and processed to remove impurities. Once it is ready for sale, it is transported to a manufacturing plant or metal refinery. The extraction of natural resources can be a costly and dangerous process. It can also harm the environment if not done responsibly. The extraction of raw materials accounts for a significant negative percentage of the total environmental load of a system or a product. Therefore, the raw materials’ extraction phase must be considered carefully when conducting an LCA. It is also a complex process regarding the data required, the evaluation’s system boundaries, the evolved sub-processes, and the energy used. This phase is also referred to as the “grave.” At the same time, the final disposal of a product generated from raw materials is called the “grave” or the End-of-Life (EoL) phase or simply the waste management phase.

The Phases of LCA

An LCA is a list and analysis of a product’s or service’s environmental effects over its entire life cycle. LCA tries to find and measure a product’s or service’s environmental impact from “cradle to grave.” This includes getting the raw materials, making the product, packaging it, distributing it, using it, and throwing it away. LCA has been used for over thirty years to determine how products and services affect the environment. The International Organization for Standardization (ISO) released standards relating to LCA in the 1990s. LCA has become a well-established part of the product and environmental assessment. As LCA is an environmental assessment tool, it can be used at any stage of product development. LCA can be used to:

- Evaluate the environmental impacts of products and services.

- Identify and measure the ecological benefits and costs of products and services.

- Assessing the environmental performance of products and services.

- Identify vital ecological aspects of products and services.

- Support decision-making about products and services.

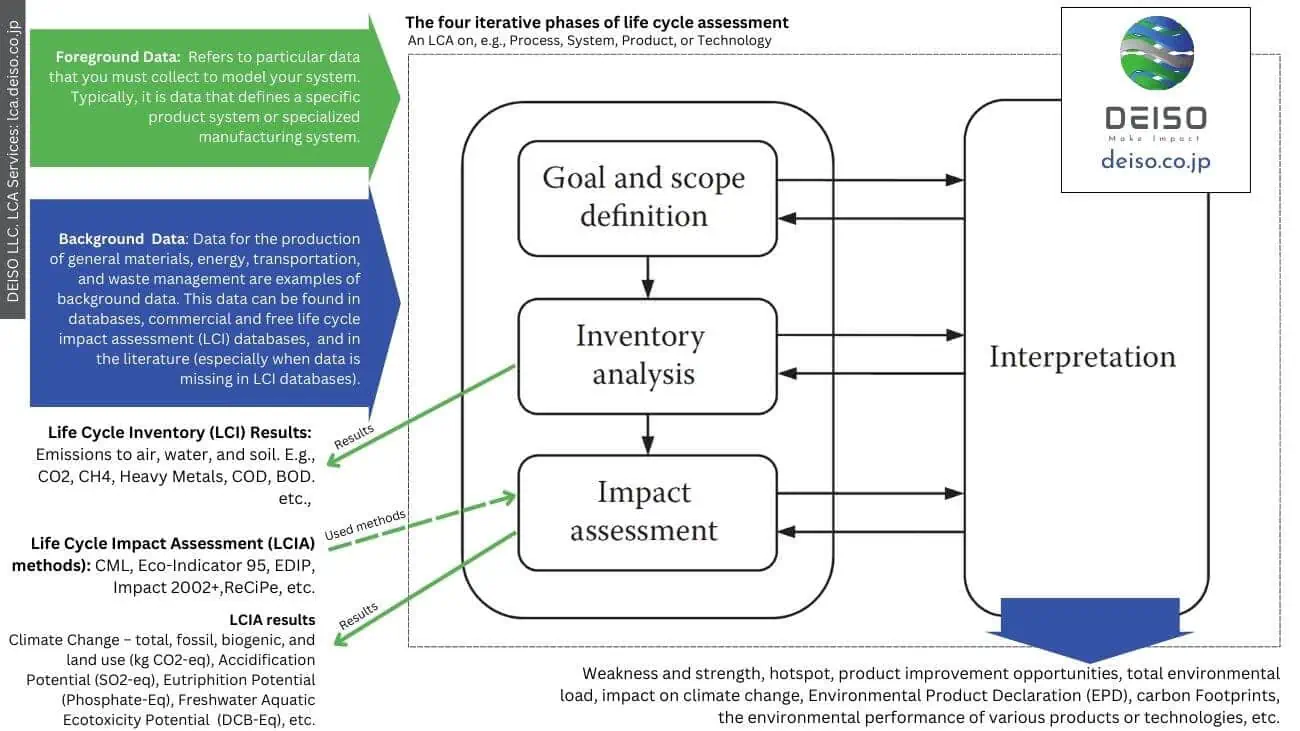

The four main phases of an LCA are Goal and scope – The phase in which the goal, the scope, the system boundaries of evaluation, and the functional unit (the reference unit) all are determined. The available unit (e.g., the production of 1 kg of plastic, is used to compare another alternative at a 1 kg reference unit). Or to estimate the impact of 1 kg, then by multiplying it by the total production amount, we can get the net environmental impacts of daily, monthly, or yearly production of a specific type of plastic. Inventory phase – identifies and quantifies a product’s or service’s environmental impacts. Impact assessment phase – determines the significance of the environmental impacts identified in the inventory phase. And finally, the interpretation and communication of the results. Below are the general steps for conducting LCAs:

- Establish the boundaries (scope) of the study.

- Select the product or service to be assessed.

- Identify and characterize the environmental impact categories.

- Develop a methodology for estimating ecological impacts.

- Estimate environmental impacts.

- The impact assessment phase of an LCA generally involves these steps:

- Evaluate the environmental effects of the product or service.

- Identify and measure the ecological benefits and costs of products and services.

- Assessing the environmental performance of products and services.

- Identify vital ecological aspects of products and services.

- Support decision-making about products and services.

- The interpretation and communication of the results phase of an LCA generally involve these steps:

- Preparing an LCA report.

- Communicating the results of the LCA.

Life Cycle Impact Assessment (LCIA)

The LCIA is a vital step of the LCA that must be completed. CML, ReCiPe, TRACI, and other LCIA methodologies have been developed to evaluate the environment. These approaches have two levels of evaluation: the Mid-Point and the End-Point.

The majority of LCIA procedures are at the Mid-Point level. Few, such as the ReCiPe approach, give an End-Point level evaluation. End-Point environmental themes such as Global Warming Potential (GWP), Human Toxicity Potential (HTP), Acidification Potential (AP), Energy Depletion, Eutrophication Potential (EP), Ozone Layer Depletion (OLD), and others are frequently aggregated into damage categories such as Damage to Health, Damage to Ecosystem, and Damage to Natural Resources (11+ environmental themes are aggregated into three major ecological indicators). Choosing an appropriate LCIA approach is typically tricky. A literature study of industry reports and peer-reviewed academic studies is one way to this difficulty.

Environmental Themes:

- Environmental themes, also known as “environmental loads” or “environmental impact categories,” are the results obtained from the LCIA phase, for example, the “climate change” or the GWP. Others include, e.g., the HTP. Below is an example of the environmental themes often evaluated with LCA.

- Abiotic Elements Depletion (ADE): ADE (measured in kg Sb-Eq) is the effect of natural resource exploitation. It is the difference between resources used throughout the waste life cycle and resource consumption.

- Abiotic Depletion of Fossil (ADF): The ADF (expressed in MJ) relates to resource depletion (e.g., energy and non-renewable energy resources, such as natural gas).

- AP: AP impacts are represented in kg SO2 eq. It is the quantity of H+ ions created per kilogram of material compared to SO2. Consequently, it represents the greatest amount of acidification a material may induce.

- EP: Expressed in kilograms, phosphorus-equivalent is the possibility that fertilizers would over-fertilize water and soil.

- Freshwater Aquatic Ecotoxicity Potential (FAETP): The FAETP (expressed in kg of DCB-Eq) quantifies the negative impact of toxic chemicals on aquatic life.

- GWP: The GWP (given as kg of CO2-Eq) is well-known as the potential for climate change. It is a method of measuring climate change.

- HTTP: HTP (in kg DCB-Eq) reflects chemical emissions, such as heavy metals, to which humans are exposed.

- Terrestris Ecotoxicity Potential (TETP): The TETP (expressed in kg of DCB-Eq) refers to the hazardous chemicals’ impacts on terrestrial ecosystems.

LCA Data

Despite extensive secondary data, some processes or materials are often unavailable in the LCA databases. Data gathering is the most challenging part of doing an LCA. Depending on your time and resources, missing data can be collected or estimated in several ways. There are two types of data helpful to distinguish:

- Foreground data is specialized data that describes a particular production system or product system needed for system modeling.

- Background data: Databases of emission factors and literature contain background data related to manufacturing generic materials, energy, transportation, and waste management.

Life Cycle Inventory (LCI)

LCI databases of the emission factors represent the environmental impact of products per functional unit and materials throughout their life cycles. The databases contain information on the materials and energy used in the production of products and the waste generated during their use and disposal. This information can assess the environmental impact of products and materials at each life cycle stage, from raw material extraction to final disposal. LCI databases can also compare the environmental impact of different products and materials and identify opportunities for reducing their environmental impact.

Examples of LCI Databases:

- ecoinvent database: The ecoinvent database is the world’s top LCI database, with broad coverage for country-specific processes in industrial nations. The database also includes a lengthy procedure categorized as China-Data or Global Data. It gives detailed process data for hundreds of processes, allowing users to make educated decisions regarding the environmental effect of their choices.

- IDEA for Environmental Analysis (IDEA): IDEA is the industry-leading LCA database in Japan. It encompasses the majority of the Japanese business’s economic operations of production. It includes around 3,800 processes based on the Japan Standard Commodity Classification. Recently, the database has grown in popularity and is now accessible with various LCA tools (SimaPro and openLCA).

The IDEA and ecoinvent databases include 3,800 processes and 18,000 activities, respectively. The second, extensively utilized, is often updated with new approaches. It should be noted that popular LCI databases such as ecoinvent and GaBi Professional, as well as their database extensions, include various country-specific techniques, including those from Japan.

Definition of the Four LCA Phases

The Four Iterative Phases of LCA

Phase 1: Goal and Scope Definition

The LCA study is outlined in the goal and scope definition, and the objectives and scope of the investigation are described. Several critical aspects are determined during this step: the system’s function, the functional unit on which emissions and extractions will be based, and the system boundaries. Both the base scenario and the options are discussed.

Phase 2: Inventory Analysis

The harmful emissions to air, water, and soil, and the extractions of renewable and non-renewable raw materials, are quantified in the inventory study. The resources necessary for the system to function are also decided here.

Phase 3: Impact Assessment

Among the steps in the impact assessment are:

- Establishment of impact categories, category indicators, and characterization factors.

- Assessment of environmental consequences (global warming, human toxicity, ecotoxicity, resource use, etc.)

- Classification of emissions that contribute to each category of environmental impact. End-Point characterization weights and aggregates emissions into impact categories based on their Mid-Point.

- Damage characterization combines impact categories to create damage categories (damage to human health, ecosystem quality, resources, etc.).

- An additional normalizing step may be performed to demonstrate the examined product’s contribution as a fraction of the global impact in a particular category.

- Finally, a socially based weighting might be applied to the impact evaluation to account for the relative importance—or damage—. Four. Interpretation The results acquired are analyzed, and the uncertainties are examined. Sensitivity studies and uncertainty propagation can identify the main parameters and improvement alternatives. A critical analysis assesses the impact of the specified boundaries and hypotheses. Finally, environmental repercussions might be weighed against economic or societal consequences.

Phase 4: Interpretation

The interpretation is where the results are interpreted, and the uncertainties are assessed. A critical analysis assesses the impact of the specified limits and hypotheses using sensitivity studies and uncertainty analysis (Monte Carlo Simulation) to identify the main parameters and improvement alternatives. Finally, environmental consequences might be weighed against economic or societal repercussions.

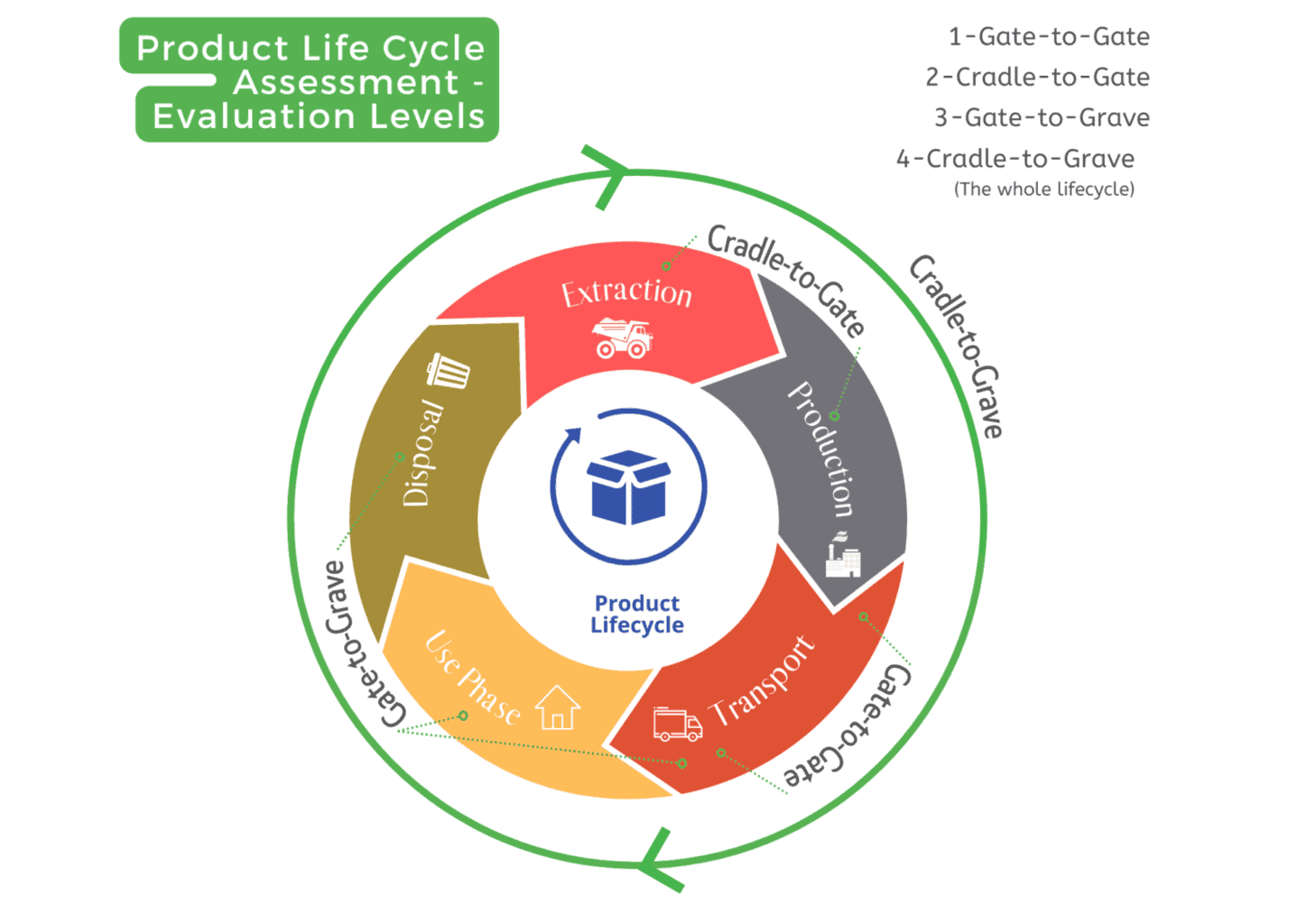

Evaluation Levels

There are three levels of evaluation within a system boundary in an LCA study and within its dataset of a particular process. It depends on the kind of dataset, whether it is a ‘gate to gate’ unit process, an ‘aggregated’ process, or even an ‘aggregated from the cradle to the grave’ process that determines what is included in the dataset.

- Gate to Gate: All company or site-related operations starting with material acquisition or procurement and continuing through all manufacturing processes on-site until final steps before departing the site gates.

- Cradle-to-Gate: All operations from resource extraction through the final stages before exiting the site gates, including all energy and precursor production steps and on-site production.

- Gate to grave: This level expands the operations from the gate level to the final disposal.

- Cradle to the grave (the whole life cycle): Cradle-to-Gate extended through a product’s usage, maintenance, and EoL (disposal, recycling, and reuse).

Evaluation Levels in an LCA Study

The Benefits of DEISO's LCA Services for Your Company

DEISO’s LCA services help companies understand how their products, processes, and supply chains affect the environment and establish an environmental profile for products and companies. This information will help them better decide to improve the entire industry’s sustainability.

Getting Started with LCAs for Your Commercial Project or Research?

Visit https://dei.so/lca-training to learn more about our LCA training programs.

Share this:

- Email a link to a friend (Opens in new window) Email

- Share on LinkedIn (Opens in new window) LinkedIn

- Share on X (Opens in new window) X

- Share on Facebook (Opens in new window) Facebook

- Share on WhatsApp (Opens in new window) WhatsApp

- Share on Reddit (Opens in new window) Reddit

- Print (Opens in new window) Print

- More