Process Engineering: Transform Your Processes. Drive Sustainable Impact.

The Role of Process Engineering in Environmental Sustainability

Process engineering is one of the most critical disciplines for addressing global environmental challenges. It provides the scientific and technical foundation for designing, optimizing, and improving industrial systems — enabling industries to reduce environmental impact, enhance energy efficiency, and integrate sustainability at the process level.

Unlike general engineering disciplines that focus on outputs or structures, process engineering zeroes in on the transformation of materials, energy, and chemicals through controlled systems. These systems are responsible for manufacturing nearly everything we consume — from fuel and pharmaceuticals to food, semiconductors, and building materials.

In the age of climate crisis, resource scarcity, and ESG-driven transformation, process engineering plays an irreplaceable role in:

🌍 Reducing GHG emissions through cleaner process design and energy recovery systems

♻️ Enhancing material circularity by designing recovery, reuse, and recycling stages into process flows

📉 Lowering carbon and water footprints using integrated simulation and LCA modeling

🧮 Supporting compliance with LCA standards, EPD frameworks, and ESG disclosure requirements

🧠 Advancing innovation through AI-powered optimization, predictive control, and dynamic simulation

Process engineers today must consider not only operational efficiency and cost, but also how their systems align with:

Engineering Toolchain & File Formats Commonly Used in Process Engineering Projects

To execute high-quality process engineering and sustainability-driven modeling, engineers must leverage a comprehensive toolchain — one that ensures interoperability between simulation software, CAD models, and sustainability analysis platforms. At DEISO, our engineering workflows are structured to accept and operate across a variety of technical file formats that support deep modeling, cross-team collaboration, and process transparency.

We work with and support the following file types and software categories:

Aspen Plus (

.bkp) – Used for steady-state process simulation, often in chemical manufacturing and utilities.Aspen HYSYS (

.hsc,.prz) – Ideal for oil & gas, LNG, and complex thermodynamic systems.AutoCAD (

.dwg) and SolidWorks (.sldprt,.sldasm) – For equipment modeling, piping, pressure vessels, and 3D plant design.STEP / IGES – Exchange formats for CAD interoperability in equipment and assembly designs.

PFDs / P&IDs – Core engineering deliverables representing flow structure and instrumentation control.

LCA files (

.lci,.ecoSpold v1 and v2,Zolca) – Used to integrate life cycle inventory data and simulate sustainability outcomes.CSV, Excel, and JSON – Data formats that enable batch data import/export, interoperability with dashboards, and compatibility with DEISO Visly/Satori AI.

Simulation Data Logs – Structured outputs used for process control, PID tuning, and performance tracking over time.

At DEISO, we follow a 5-phase project workflow to ensure clarity, performance alignment, and measurable outcomes across every engineering engagement. This workflow allows us to move from strategy to implementation with engineering precision, while embedding environmental intelligence at every step.

Phase 1: Discovery Meeting

We begin with a focused stakeholder session to understand the full picture: project goals, system constraints, regulatory context, sustainability objectives (e.g., emission targets, EPD requirements), and desired outcomes. This ensures our modeling scope aligns with real-world operational expectations.

Phase 2: Data & Site Collection

Our engineers collect structured baseline data — from flow rates and thermal profiles to equipment specs, material inputs, and emissions data. We also collect metadata needed for LCA, GHG reporting, and compliance.

Phase 3: Simulation & LCA Modeling

We then simulate your process systems using tools like Aspen Plus, HYSYS, or custom-coded models. At this stage, we embed LCA parameters, emission factors, and energy balances into the process logic to identify critical environmental hotspots and efficiency gaps.

Phase 4: Visualization & Reporting

Outputs are converted into visual dashboards, LCA impact tables, Sankey diagrams, and ESG-focused analytics. Using DEISO Visly and Satori AI, we present decision-ready insights for engineers, managers, and sustainability teams alike.

Phase 5: Final Delivery & Support

We deliver not only the technical package — models, reports, diagrams — but also conduct structured training for your internal team. This ensures long-term operability, adaptability, and value capture across departments.

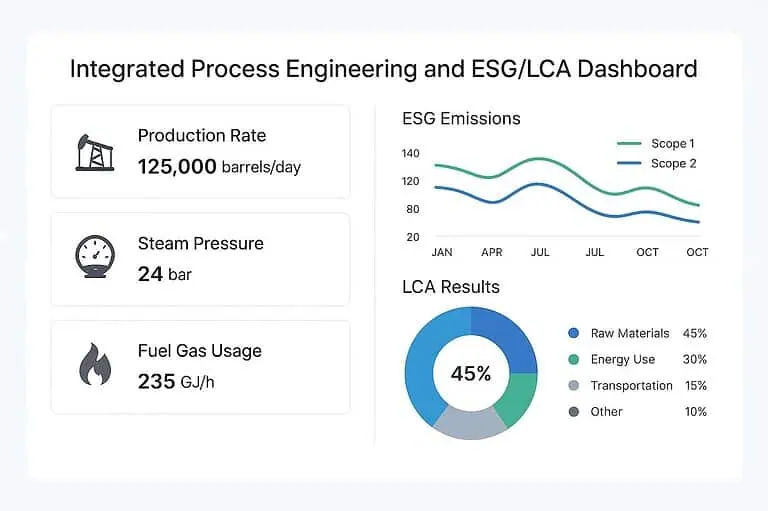

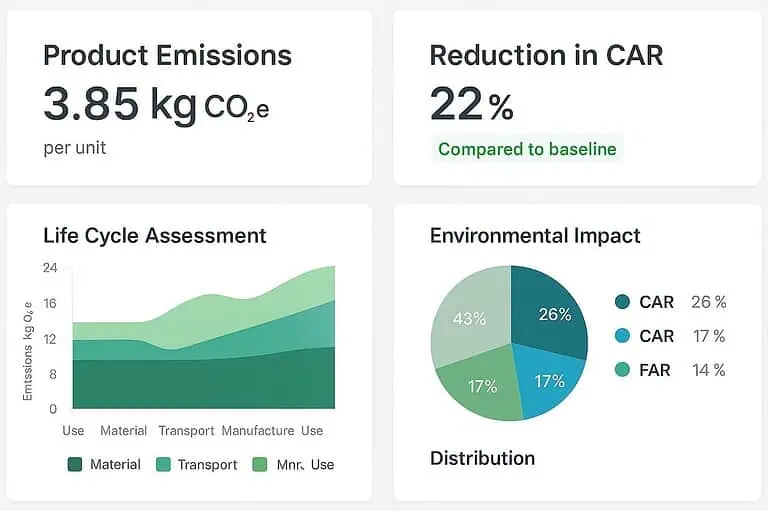

Data, Visualized: Dashboards That Drive Action

Data is only useful when it leads to action. That’s why DEISO transforms technical simulation, LCA modeling, and emissions tracking into interactive dashboards and visual reports — empowering teams across your organization to engage, respond, and improve processes continuously.

Our dashboard systems are powered by DEISO Visly and Satori AI, purpose-built to support sustainability-linked process engineering. These platforms translate complex technical models into intuitive interfaces that connect engineering outputs to key decision metrics.

Dashboards We Deliver Include:

🔍 Scope 1–3 emissions mapping by process segment or equipment

🌡️ Energy, material, and water consumption trends over time

♻️ LCA impact category breakdowns aligned with ISO and EPD standards

📊 Efficiency vs. cost visualizations for continuous improvement

🔮 Predictive analytics: impact of operational changes on sustainability KPIs

📤 Export-ready ESG outputs for CSR, GRI, and TCFD reporting

Our dashboards are designed for:

Engineers and plant managers who want performance clarity

Sustainability officers tracking LCA and ESG metrics

Executives making CAPEX, compliance, and procurement decisions

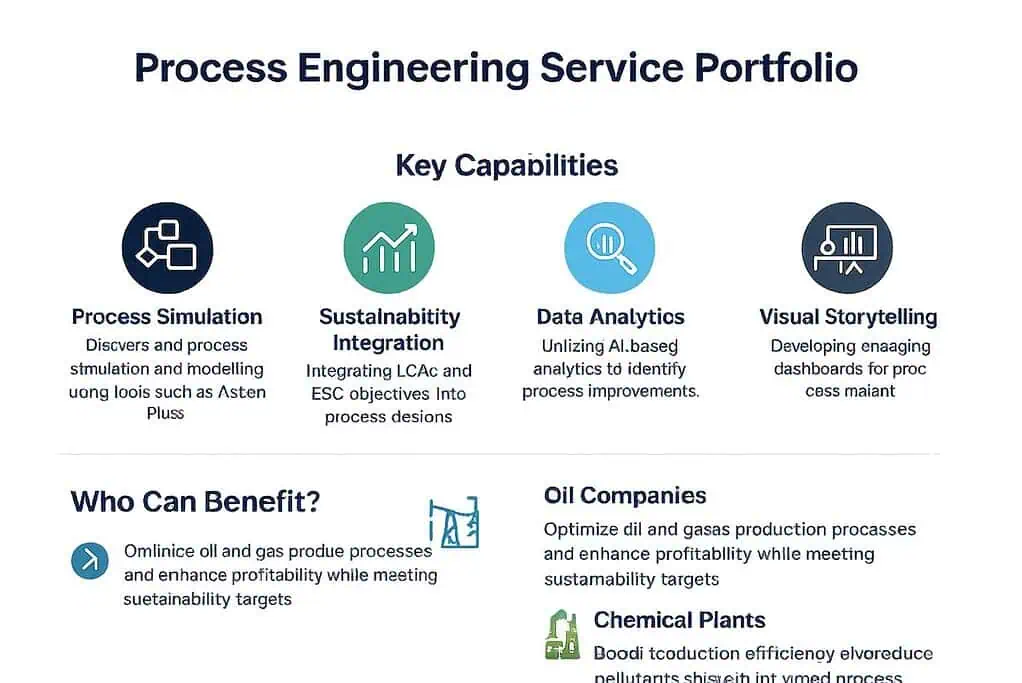

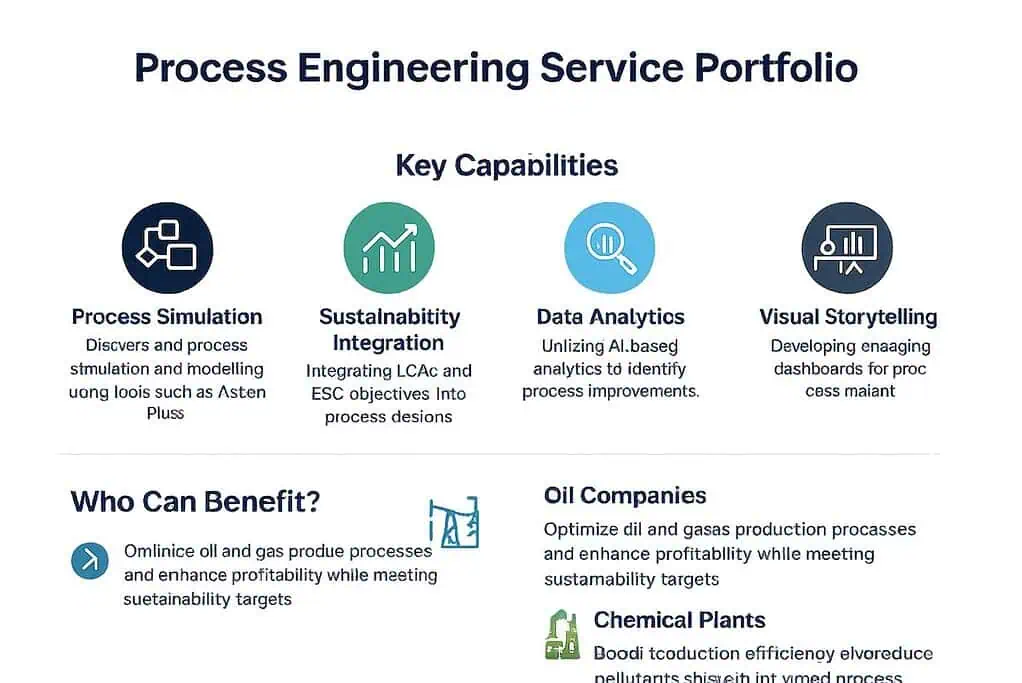

Who Is This For?

DEISO’s process engineering services are designed to serve clients across a wide spectrum of industries where materials, energy, emissions, and sustainability are critical to operations and compliance. Whether you’re dealing with large-scale manufacturing or process-driven utility infrastructure, our simulation and LCA-integrated approach is engineered to deliver measurable improvements.

We support both upstream and downstream processes, complex multiphase systems, emissions-critical workflows, and circular economy applications.

Key Sectors We Serve:

⛽ Oil & Gas: Upstream operations, refining, gas treatment, flare minimization

⚗️ Chemical Manufacturing: Batch/continuous reactors, separation units, heat exchangers

⚡ Utilities & Energy Producers: Grid-connected thermal systems, cogeneration, hydrogen

🧃 Food, Beverage & Agri-Manufacturing: Steam integration, water reuse, packaging lines

🏗️ Construction & Building Products: EPD-linked production lines, cement, asphalt, composites

🪨 Mining, Metallurgy & Material Firms: Leaching, recovery, high-temperature processes

🔋 Electronics & Waste Treatment: Hazardous waste handling, closed-loop material flows

🧱 Advanced Manufacturing & Circular Systems: LCA-modeled processes, zero-waste designs

Our engineering methods are scalable across industries but always tailored to your facility’s data, emissions footprint, and operational needs.

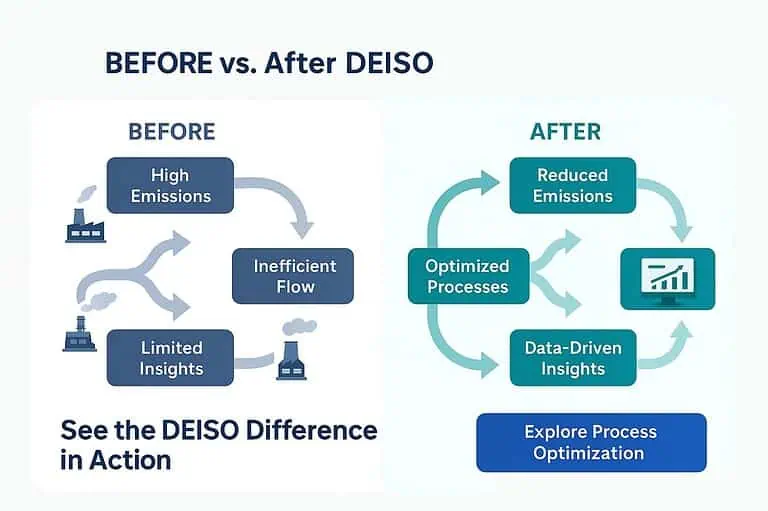

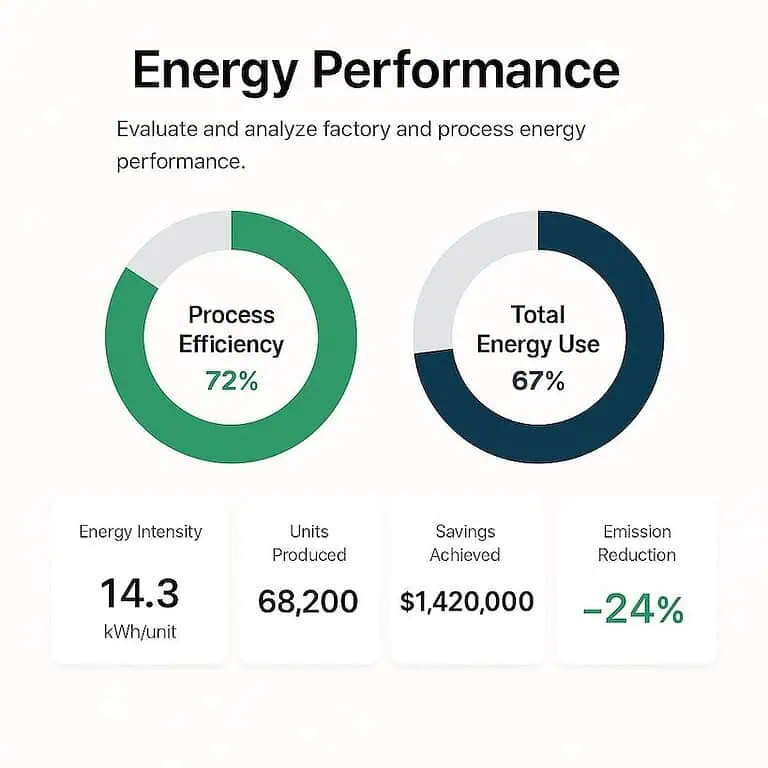

Let’s Talk Numbers: Results That Matter

DEISO’s process engineering services are built not just for modeling — but for performance. Every engagement is measured by its real-world results: emissions reductions, energy savings, improved process timing, and strategic ROI. Our multidisciplinary model ensures that engineering solutions yield business value and sustainability compliance simultaneously.

Here’s what our clients have achieved:

📉 ~27% decrease in total process cycle time by eliminating bottlenecks and inefficiencies

🔋 20–35% energy use optimization through thermodynamic recalibration and recovery systems

📈 Up to 600% ROI within 12 months of system implementation, driven by cost savings and compliance readiness

🌐 Comprehensive Scope 1–3 emissions tracking, fully integrated with LCA databases and audit frameworks

✅ Seamless integration of ESG and EPD standards into operational reporting and corporate disclosures

These metrics are not theoretical — they’re the direct result of our rigorous simulation and sustainability modeling, tailored to your site, systems, and compliance goals.

DEISO doesn’t just help you meet benchmarks — we engineer the systems that define them.

DEISO AI: Accelerating Process Engineering with Environmental Intelligence

In the realm of process engineering, where precision and sustainability converge, DEISO AI stands as a transformative force. By integrating advanced artificial intelligence into engineering workflows, DEISO AI enhances the efficiency, accuracy, and environmental compliance of industrial processes.

Key Features of DEISO AI in Process Engineering:

Advanced Simulation Analysis: DEISO AI processes complex simulation data, identifying patterns and anomalies that might be overlooked in traditional analyses. This leads to more informed decision-making and optimized process designs.

Environmental Impact Assessment: Leveraging vast datasets, DEISO AI evaluates the environmental implications of engineering processes, ensuring alignment with sustainability goals and regulatory standards.

Predictive Maintenance: By analyzing equipment performance data, DEISO AI predicts potential failures, allowing for proactive maintenance and reducing downtime.

Resource Optimization: DEISO AI identifies areas where energy and material usage can be reduced without compromising output, leading to cost savings and reduced environmental impact.

Customized Reporting: The platform generates tailored reports that translate technical data into actionable insights for stakeholders at all levels.

Applications Across Industries:

DEISO AI’s versatility makes it applicable across various sectors, including:

Chemical Manufacturing: Optimizing reaction conditions and resource utilization.

Energy Production: Enhancing efficiency in power generation and distribution.

Water Treatment: Streamlining purification processes and monitoring environmental compliance.

Pharmaceuticals: Ensuring quality control and regulatory adherence in production lines.

By embedding DEISO AI into process engineering, organizations not only achieve operational excellence but also contribute to broader sustainability objectives.

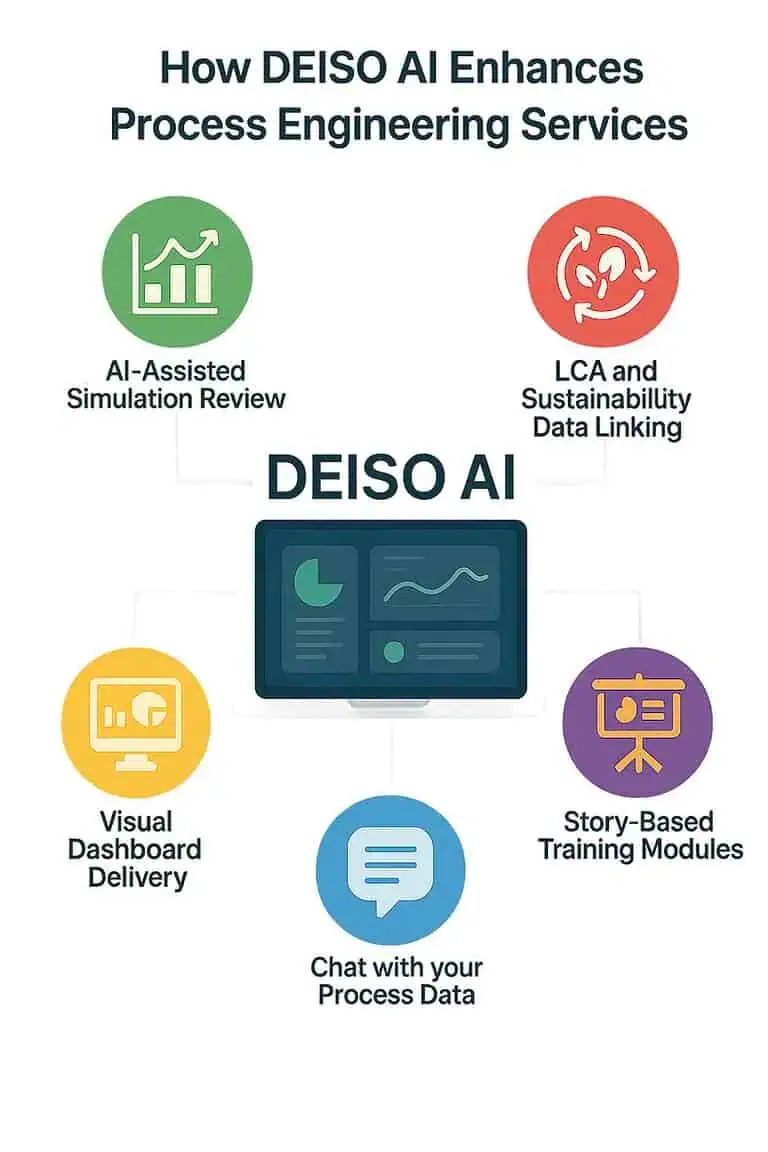

How DEISO AI Enhances Process Engineering Services

DEISO AI transforms conventional process engineering by embedding intelligent tools into every stage of modeling, analysis, and communication. Our proprietary platforms — Visly, Satori AI, Sansu AI, and DEISO Copilot powered by DEISO Spark — bring engineering clarity and sustainability insight to the forefront.

By integrating DEISO AI with your engineering projects, you gain:

-

AI-assisted simulation review – Interpret results from Aspen Plus, HYSYS, or other engineering tools using intelligent assistance to spot inefficiencies, emission hotspots, or performance anomalies.

-

LCA and sustainability data linking – Integrate

.lci,.ecoSpold v1/v2, andZolcafiles with your engineering workflows to connect operations with life cycle-based impact modeling. -

Visual dashboard delivery – Build interactive dashboards with DEISO Visly and Satori AI, translating raw data into actionable insights on energy, emissions, and ESG indicators.

-

Story-based training modules – Powered by Sansu AI, our training delivers simulation walkthroughs, embedded technical narratives, and interactive charts to help engineers learn and retain critical insights.

-

Chat with your process data – Use DEISO Copilot (built on DEISO Spark) to interact with your engineering files and sustainability datasets. Ask questions, explore trends, and extract impact metrics — all in real time, without writing a single formula or script.

-

Standards-ready output – Ensure that all deliverables align with ISO 14040/44, ISO 14067, and EN15804 frameworks, ready for EPD, GHG, and ESG reporting.

With DEISO AI, process engineers don’t just build systems — they understand them better, teach them clearly, and optimize them sustainably.

Industries and businesses we serve

DEISO delivers tailored data analysis, visualization, and storytelling solutions to enterprises with complex sustainability and reporting needs. Our clients span critical industries where environmental performance is a strategic priority.

We work with enterprise clients in industries such as:

🏭 Chemical manufacturing and engineering

⚡ Energy and utilities

🛢 Oil and gas

🧪 Electronics and semiconductors

🏗 Construction and building materials

🚗 Automotive and transportation

🌱 Environmental consulting

🔬 Industrial equipment and systems

📦 Packaging and materials

🌐 Infrastructure and public-sector enterprises

Share this:

- Email a link to a friend (Opens in new window) Email

- Share on LinkedIn (Opens in new window) LinkedIn

- Share on X (Opens in new window) X

- Share on Facebook (Opens in new window) Facebook

- Share on WhatsApp (Opens in new window) WhatsApp

- Share on Reddit (Opens in new window) Reddit

- Print (Opens in new window) Print

- More